A well seal is an essential component in the water well system. It protects the wellhead from contamination and ensures the system runs efficiently. Among the various types of well seals, the Simmons 4-inch well seal is a reliable and popular choice for residential and commercial water well applications.

This article will guide you through understanding the Simmons 4-inch well seal, its maintenance port diagram, installation tips, and helpful FAQs. We will also provide key considerations for maintaining your well seal to ensure the longevity of your water well system.

Contents

Understanding the Simmons 4-Inch Well Seal

A well seal is a protective cover on top of a well casing to prevent surface water and contaminants from entering the well. The Simmons 4-inch well seal is designed to fit well casings with a diameter of 4 inches. These seals are essential for ensuring that the groundwater extracted from the well is clean, safe, and free from pollutants like dirt, insects, and debris.

The Simmons 4-inch well seal is made of durable materials such as plastic, rubber, or a combination of both, providing a strong and reliable barrier against contaminants. The maintenance port included in the design allows easy access to the well for inspection and maintenance without compromising the seal’s integrity.

Key Components of the Simmons 4-Inch Well Seal

Before diving into the installation and maintenance process, it’s essential to understand the components of the Simmons 4-inch well seal:

- Seal Lid: This is the top part of the seal that covers the well casing opening. The lid is designed to prevent contaminants from entering the well and to ensure the seal remains intact over time.

- Seal Body: The body is the central portion of the well seal that attaches to the well casing. It provides the primary barrier against contaminants and secures the seal in place.

- Maintenance Port: The maintenance port is an essential feature of the Simmons 4-inch well seal. It provides easy access for inspections, cleaning, or maintenance activities without disturbing the seal.

- Rubber Gasket: This gasket sits between the well casing and the seal body, ensuring a tight, water-resistant fit. It helps prevent water from seeping around the seal’s edges.

- Bolts and Fasteners: These components secure the well seal to the well casing and maintain its stability. They are crucial for keeping the seal in place during heavy rainfall or other external pressures.

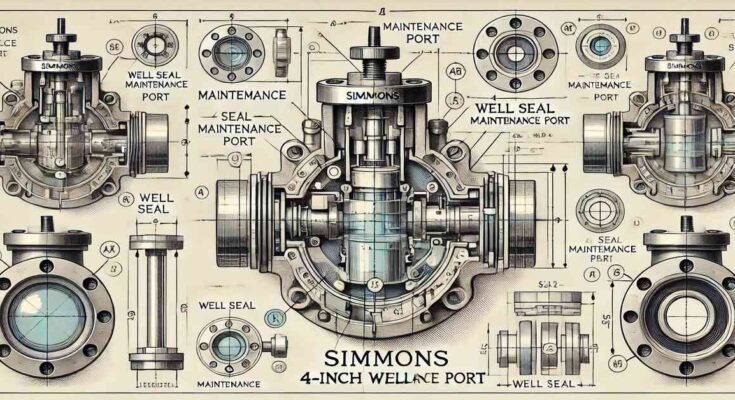

Simmons 4-Inch Well Seal Maintenance Port Diagram

The maintenance port on the Simmons 4-inch well seal serves as a point of entry for maintenance purposes and access to the well. It’s important to note that the diagram for this port typically features the following components:

- Port Lid: The removable lid that covers the maintenance port is typically designed for easy access. It may be secured with screws or other fastening methods, allowing users to open it without removing the entire seal.

- Ventilation Holes: Some maintenance port designs may feature small ventilation holes to prevent pressure buildup within the well system during inspections.

- Port Connection: The port may connect to a hose or pipe to inject cleaning solutions or remove any debris that may have entered the well during maintenance.

- Drainage System: The maintenance port may also have a drainage system to ensure any water or liquid inside the port is safely drained during cleaning or other operations.

This diagram helps installers and maintenance professionals correctly position and use the port for optimal results. For more information, consult your specific model’s official Simmons 4-inch well seal manual or diagrams.

Installation Tips for the Simmons 4-Inch Well Seal

Proper installation of the Simmons 4-inch well seal ensures a secure, durable, and long-lasting solution for your water well system. Follow these key installation tips:

- Ensure Proper Well Casing Size: Before purchasing the Simmons 4-inch well seal, double-check that your well casing has a 4-inch diameter. The seal is designed specifically for this size, and using the wrong seal can compromise the effectiveness of your well.

- Inspect the Casing and Wellhead: Before installation, inspect the well casing and the wellhead for any damage, cracks, or signs of wear. Any damage should be repaired before sealing to ensure a proper fit and prevent contamination.

- Clean the Casing Opening: Ensure the top of the well casing is clean and debris-free. Dirt or obstructions can interfere with the gasket’s proper sealing, resulting in an ineffective seal.

- Use a Rubber Gasket for Proper Sealing: Place the rubber gasket between the well casing and seal body. This gasket helps form a watertight seal, preventing surface water or contaminants from entering the well.

- Secure the Seal with Bolts and Fasteners: Tighten the bolts and fasteners around the perimeter of the well seal to ensure it stays securely in place. Use a wrench to tighten the bolts evenly and avoid over-tightening, which could damage the seal or casing.

- Install the Maintenance Port Lid: If your Simmons well seal includes a maintenance port, secure the maintenance port lid in place using screws or other fasteners. Make sure the lid is tightly sealed to prevent any water from entering.

- Perform a Leak Test: After installation, perform a leak test to ensure the seal functions correctly. Pour water around the perimeter of the seal and check for any signs of leakage or gaps.

- Check for Ventilation: If the well seal includes ventilation holes, ensure they are unobstructed and debris-free. Ventilation is essential for the well’s airflow and pressure regulation.

- Regular Maintenance: Inspect the well seal to ensure it remains intact. Ensure the maintenance port is free from obstructions and that the rubber gasket maintains flexibility and effectiveness.

Conclusion

The Simmons 4-inch well seal with a maintenance port is essential to any water well system. By understanding its components, installation process, and maintenance requirements, you can ensure that your well operates efficiently and remains free from contaminants. Proper installation is key to ensuring the longevity of your water well system and preventing any costly repairs or contamination issues in the future.

By following the tips outlined in this article and performing regular maintenance, you can extend the life of your well seal and maintain a clean, safe water supply for your household or business. Always consult professional help if you’re unsure about installation or maintenance.

FAQ

How often should I check the Simmons 4-inch well seal?

It’s a good idea to check it at least once a year or after significant rainfall or storms. Regular inspections help identify issues before they become serious problems.

Can I install the Simmons 4-inch well seal myself?

You can install the healthy seal yourself if you have the necessary skills and tools. However, if you’re unsure or unfamiliar with the process, hiring a professional is recommended.

What should I do if the well seal begins to leak?

If you notice any leaks, it’s essential to inspect the seal and rubber gasket for damage. You may need to replace the gasket or adjust the bolts to ensure a tighter fit.

How can I maintain the maintenance port?

To maintain the maintenance port, ensure it is debris-free and check for any cracks or wear in the lid. Tighten the lid if it becomes loose and ensure that ventilation holes are clear.

Can I use a Simmons 4-inch well seal for a well casing of different sizes?

No, the Simmons 4-inch well seal is designed for 4-inch well casings. Using it for a different size could lead to leaks or improper sealing.